- Store

- >

- TOOLS FOR MACHINISTS

- >

- Spindle Brake Kit for Haas TL Series Lathes MY2016 and newer

Spindle Brake Kit for Haas TL Series Lathes MY2016 and newer

SKU:

$1,295.95

$1,295.95

Unavailable

per item

Static spindle brake for Haas TL series lathes MY2016 and newer for use with A2-5 (2.3") or A2-6 (3.5") spindle.

This spindle brake allows an operator to firmly hold the spindle for live-tool machining, keyway broaching, advanced automation, and fast chuck change-overs. This brake fits cleanly inside the TL series motor housing and does not interfere with the re-installation of the factory motor housing cover or spindle drip-catch box. The caliper support frame is 1/8" thick and, as such, the motor housing cover and drip-catch box sit 1/8" beyond their original location.

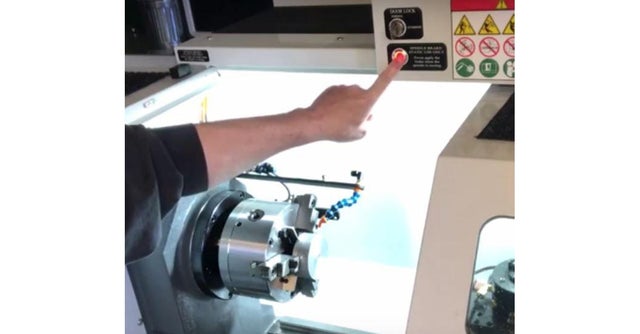

This brake may be actuated by both (or either) M-Code (relay closure) or panel mounted push-button (included). In either case, the red LED lights to warn the operator when the brake is engaged.

Typical Spindle Holding Torque vs. Pressure Setting:

This spindle brake allows an operator to firmly hold the spindle for live-tool machining, keyway broaching, advanced automation, and fast chuck change-overs. This brake fits cleanly inside the TL series motor housing and does not interfere with the re-installation of the factory motor housing cover or spindle drip-catch box. The caliper support frame is 1/8" thick and, as such, the motor housing cover and drip-catch box sit 1/8" beyond their original location.

This brake may be actuated by both (or either) M-Code (relay closure) or panel mounted push-button (included). In either case, the red LED lights to warn the operator when the brake is engaged.

Typical Spindle Holding Torque vs. Pressure Setting:

- @100 psi: 106 ft. lbs. (0.69 MPa: 122 Nm)

- @80 psi: 69 ft. lbs. (0.55 MPa: 93.7 Nm)

- @60 psi: 49 ft. lbs. (0.41 MPa: 66.8 Nm)

- @40 psi: 32 ft. lbs. (0.28 MPa: 43.4 Nm)

- @20 psi: 17 ft. lbs. (0.14 MPa: 23.0 Nm)

- Caliper support frame & Disk Brake Caliper

- Support frame hardware for flush mount of support frame

- Alloy Steel Spindle Brake Rotor & Rotor Mounting Hardware

- 110 VAC Electro-pneumatic M-Code actuator (PNEUACT)

- All 18-8 SS hardware required for installation is included

- Installation Instructions & Installation Template

- 58" M-CODE wiring cable

- 100" lighted PUSH BUTTON wiring assembly

- Installation instructions, wiring diagram, & installation template

- Difficulty: Moderate

- Installation requires careful drilling and tapping of 5 holes into the TL lathe casting as well as holes in the TL cabinet for the electro-pneumatic actuator. An experienced shop machinist can complete the installation in about 3 hours.

- Sharpie Marker, tape

- Center Punch

- Electric Drill

- Drill bits: #40, #22, #6, #15, "D", #7, 3/8", 15/32"

- Allen Wrench Sets: SAE and Metric

- Large and Small Torque Wrench

- #2 & #3 Phillips Screwdrivers

- Small flat-blade screwdriver

- Tap wrench and 1/4-20 tap

- De-burring tool for holes

- 1/4" Allen Socket Bit for Torque Wrench + 3" Socket Extension

- Wire cutters

- This brake is for static use only.

- Never apply the brake when the spindle is turning.

- Never engage spindle rotation when the brake is engaged.

- Maximum RPM: 3000

- Export shipping available on request. Contact sales for export shipping quote.

Video overview of Mathews Engineering TL-BRAKE for TL series Haas lathes:

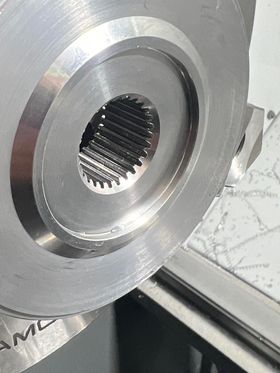

Broaching operation using M19 spindle orientation and Mathews Engineering TL-BRAKE

(video courtesy of Extreme Automatics ):

(video courtesy of Extreme Automatics ):

Example of a spline broached on TL series Haas lathe using Mathews Engineering TL-BRAKE:

(image courtesy of Extreme Automatics)

(image courtesy of Extreme Automatics)

| TL-Brake_Install_InstructionsRevF.pdf | |

| File Size: | 39278 kb |

| File Type: | |

| P_ActuatorWiringDiagram.pdf | |

| File Size: | 54 kb |

| File Type: | |

TL series M-Code relay information:

www.haascnc.com/service/codes-settings.type=mcode.machine=mill.value=M21.html

www.haascnc.com/service/codes-settings.type=mcode.machine=mill.value=M21.html